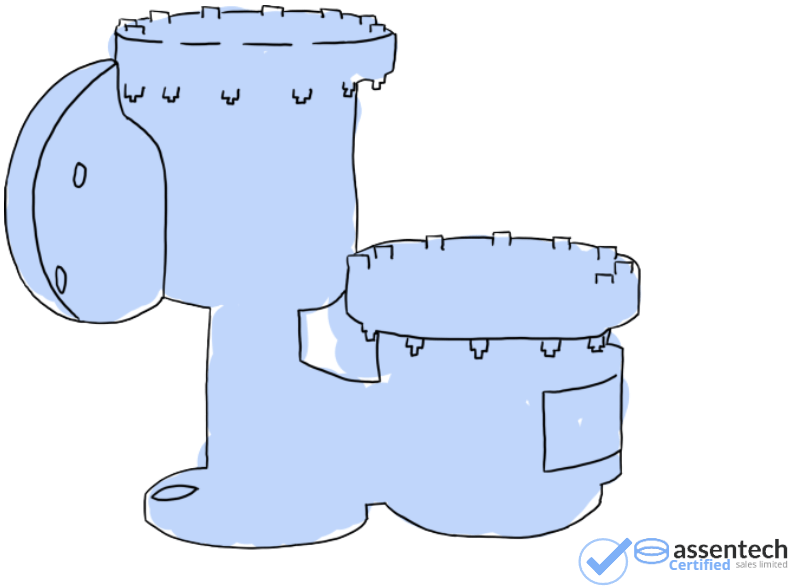

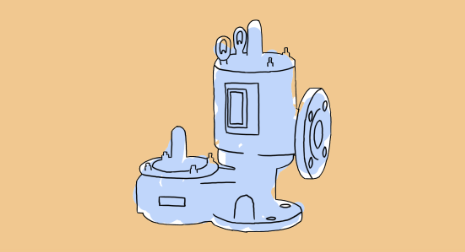

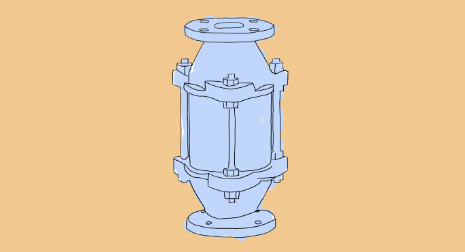

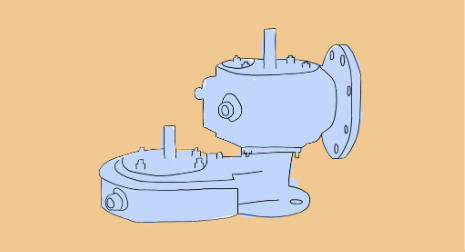

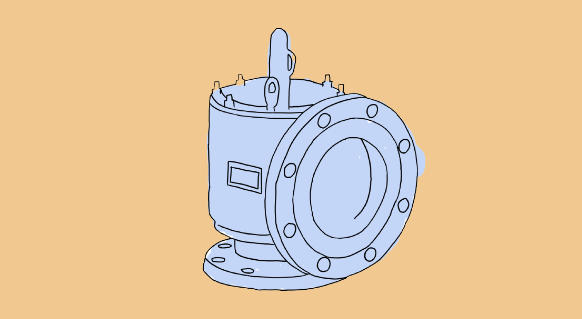

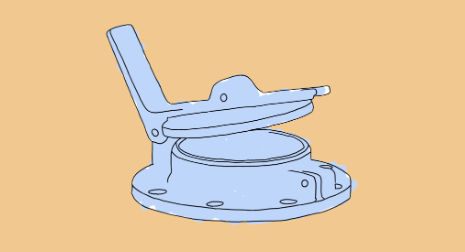

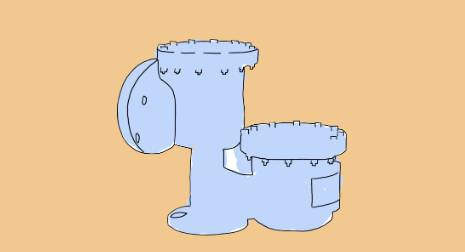

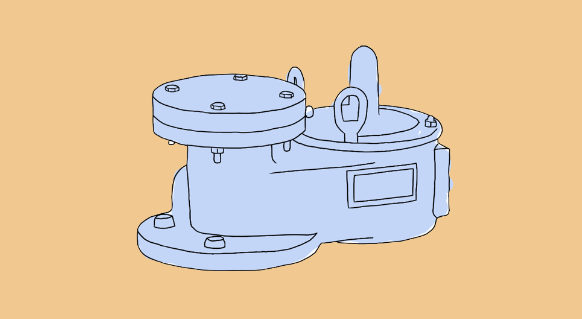

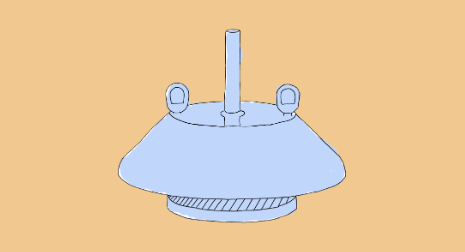

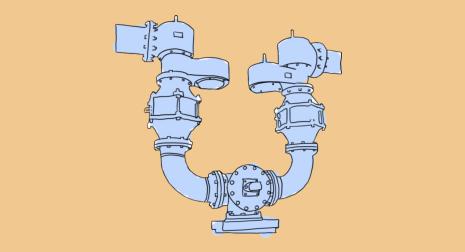

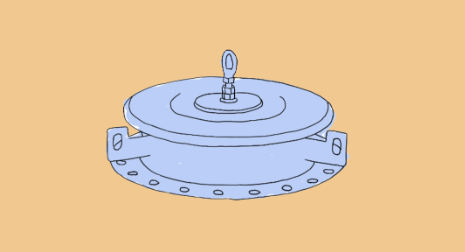

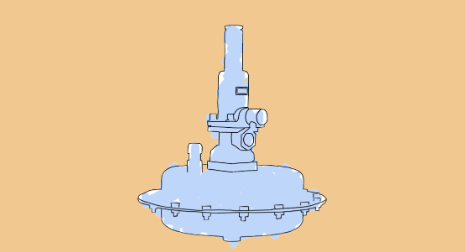

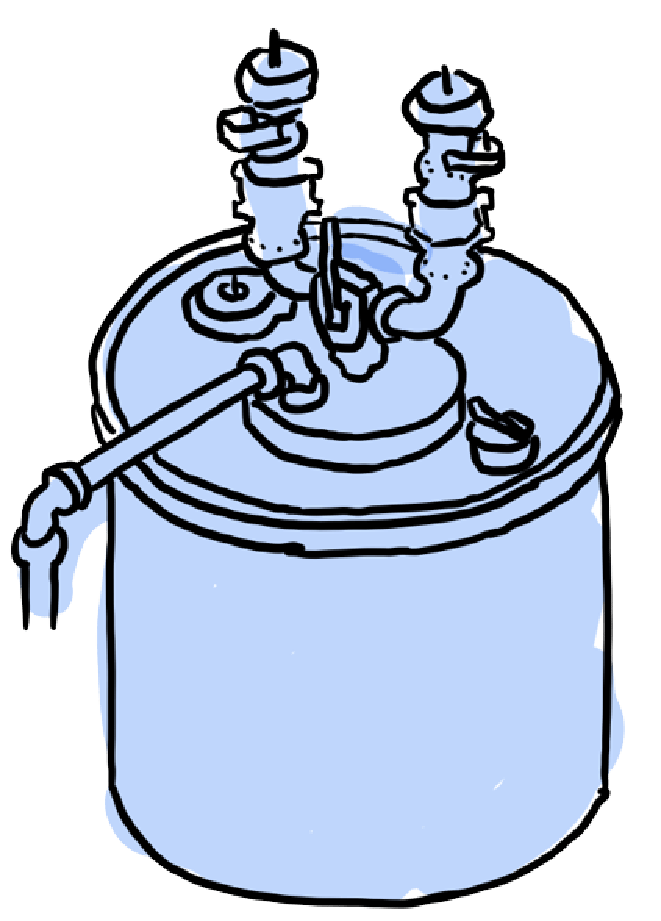

Fibreglass Breather Valves are integral to the safety and efficiency of aboveground storage tank installations, especially those housing highly corrosive and toxic liquids. These valves, while operating similarly to their metal counterparts, offer increased durability and resilience due to their fibreglass construction, making them highly resistant to harsh environments.

Their design is aimed at safeguarding your tanks from potential harm caused by over-pressuring or excessive vacuum. Additionally, they significantly curtail the costly product evaporation losses that typically occur due to tank “breathing“. This not only preserves your stored products but also reduces the risk of atmospheric contamination by effectively retaining product vapours.

What sets these fibreglass valves apart is their unique “cushioned air” seating and superior performing TEFLON® seating diaphragms that help minimise sticking caused by resinous vapours and atmospheric moisture. Other notable features include a self-draining housing body and drip rings that protect seating surfaces from condensation and freezing. This design also prevents pressure or vacuum build-up due to the binding or clogging of the valves. Moreover, they can be spring-loaded for use on blanketed tanks or other installations requiring higher settings and are equipped with peripheral guiding and a centre stabilising stem for proper alignment of seating surfaces.

For handling corrosive and toxic liquids, these Fibreglass Breather Valves are an optimal choice, ensuring your operations remain safe, efficient, and environmentally responsible.

Sizing Programme for Breather Valves available on request

| Sizing Programme for Breather Valves available on request |  |

- Fibreglass Breather Valves ensure the safety and efficiency of storage tanks, particularly when handling corrosive and toxic liquids.

- They utilise Groth’s unique “cushioned air” seating and superior TEFLON® seating diaphragms, which minimise sticking due to resinous vapours and moisture.

- Features like self-draining housing and drip rings protect against condensation and freezing, while the design prevents pressure or vacuum build-up to avoid clogging.

- These versatile valves can be spring-loaded for installations like blanketed tanks and come with peripheral guiding and a stabilising stem for proper alignment.

- Fibreglass offers a high strength-to-weight ratio, making these valves lightweight yet durable, and its corrosion resistance makes them ideal for harsh chemical environments.

- Fibreglass Breather Valves ensure the safety and efficiency of storage tanks, particularly when handling corrosive and toxic liquids.

- They utilise Groth’s unique “cushioned air” seating and superior TEFLON® seating diaphragms, which minimise sticking due to resinous vapours and moisture.

- Features like self-draining housing and drip rings protect against condensation and freezing, while the design prevents pressure or vacuum build-up to avoid clogging.

- These versatile valves can be spring-loaded for installations like blanketed tanks and come with peripheral guiding and a stabilising stem for proper alignment.

- Fibreglass offers a high strength-to-weight ratio, making these valves lightweight yet durable, and its corrosion resistance makes them ideal for harsh chemical environments.

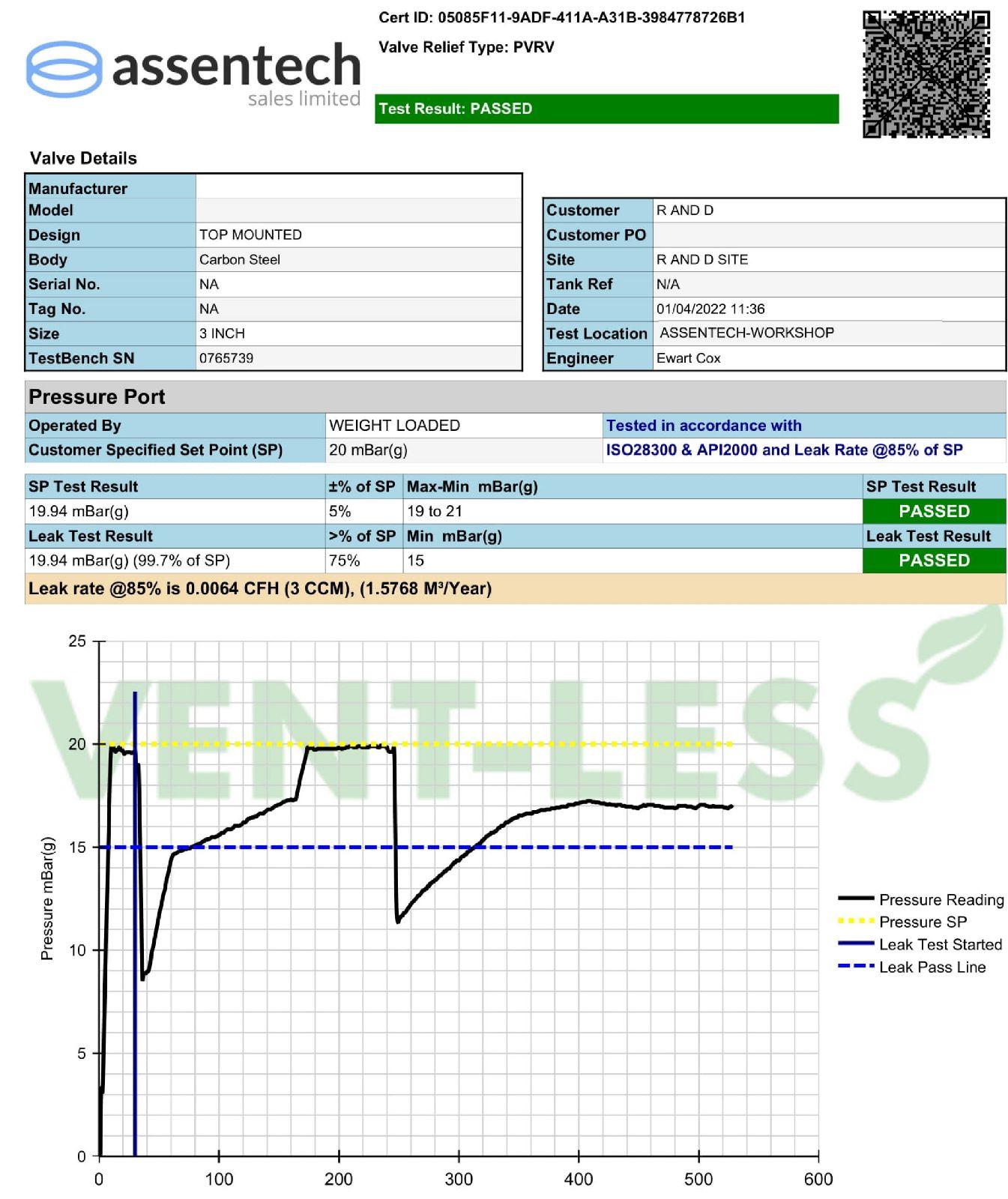

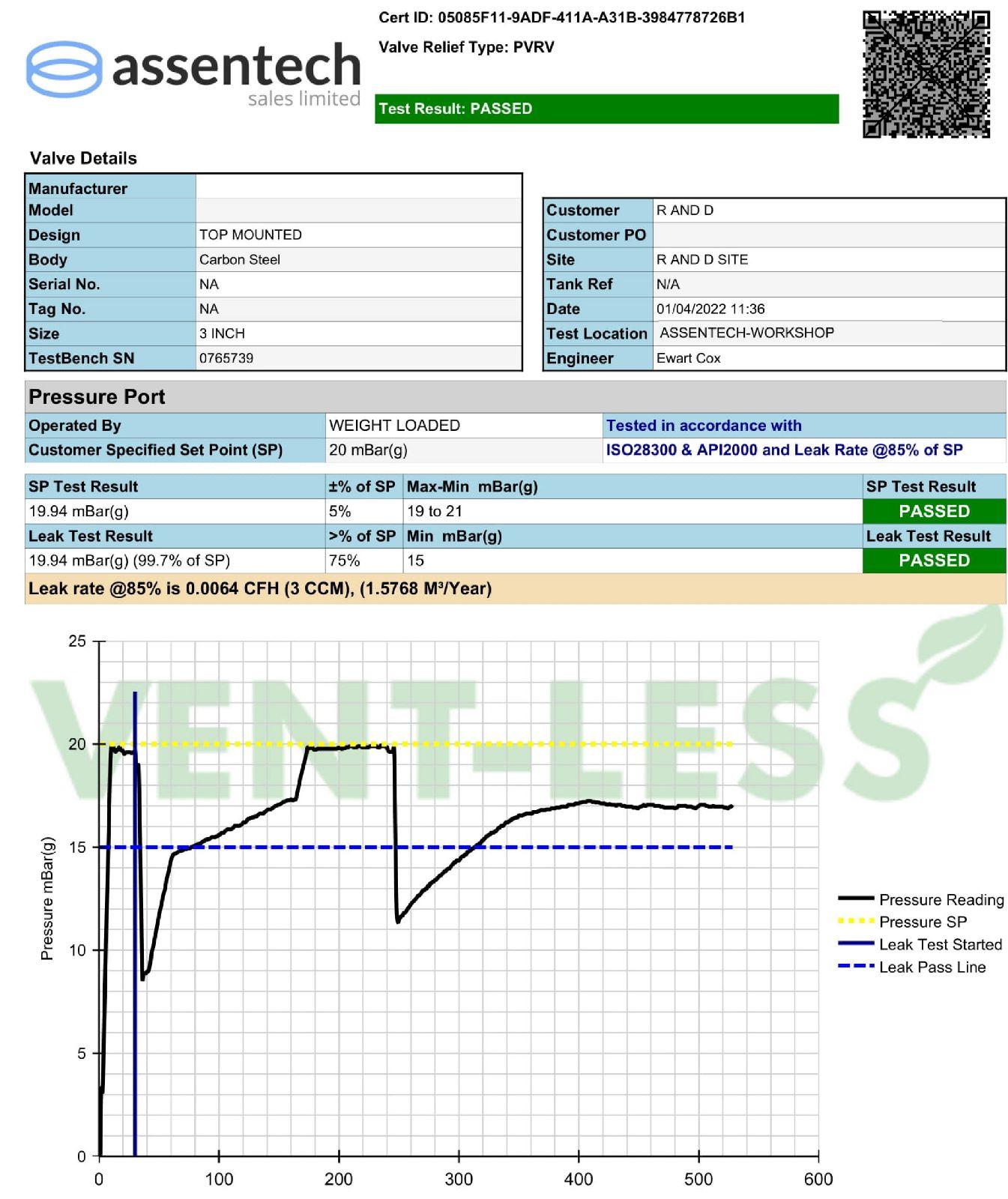

One of the defining features of our Pressure Vacuum Relief Valves is their leak-tightness. The importance of a leak-tight valve cannot be overstated in industries where even the smallest leak can lead to significant product loss, potential harm to personnel, and environmental pollution. All our valves are supplied with individual leakage and calibration certificates, as per ISO 28300 & API 2000 standards. We believe it’s important to note that while some manufacturers only supply calibration certificates, neglecting leakage tests, we ensure compliance with the aforementioned standards. Each valve we supply is tested meticulously, a process typically requiring at least an hour at the factory. This critical quality assurance step is included in our base price, reflecting our commitment to safety and quality.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation's needs.

Venting Equipment Product Range

Discover the Potential of Our Diverse Wastewater Biogas Portfolio: From Efficient Digester Cover Equipment, to Safety and Control Equipment.

Discover the Potential of Our Diverse Wastewater Biogas Portfolio: From Efficient Digester Cover Equipment, to Safety and Control Equipment.

Assentech Academy - Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact