Comprehensive LDAR (Leak Detection and Repair) Services

What is a LDAR Survey & Audit?

A Leak Detection and Repair (LDAR) survey, combined with a compliance audit, is a systematic examination of industrial equipment—such as valves, pumps, and connections—with the aim of identifying and repairing fugitive leaks of volatile organic compounds (VOCs). This process ensures that your facility meets environmental regulations, reduces emissions, eliminates product loss, and provides a documented audit trail for inspectors and compliance officers. At Assentech, our LDAR survey and audit approach is designed to deliver accurate leak detection, regulatory alignment, and a clear, professional report.

The Importance of LDAR Services

At Assentech, we are dedicated to helping industries minimise emissions and achieve regulatory compliance through our comprehensive Leak Detection and Repair (LDAR) audits and services .

Our expertise ensures that your operations are environmentally friendly, efficient, and compliant with all relevant standards. Demonstrate to your Workforce, Stakeholders and the Regulators that you are responsible.

👉 Want to see what an LDAR survey report looks like? Click here to view a demo template.

Assentech’s LDAR services help industries minimise emissions, achieve regulatory compliance, and protect the environment through advanced detection and repair technologies.

LDAR is a requirement under the Industrial Emissions Directive and forms a critical environmental function designed help operators reduce emissions and increase site efficiency and safety. LDAR planning is essential for reducing harmful emissions of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), thereby protecting public health and the environment.

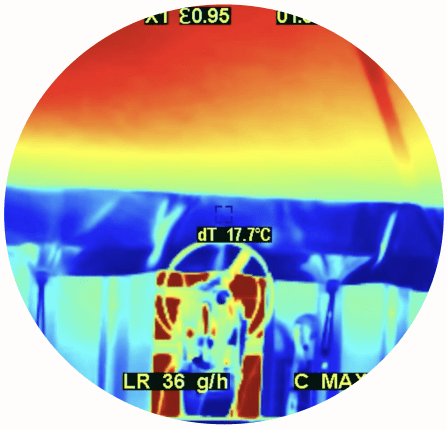

Assentech provides on-site LDAR services by working with our OGI camera specialist who use optical gas imaging and quantification technology to identify and measure fugitive emissions. This activity enables compliance with ATEX and DSEAR (Dangerous Substances and Explosive Atmospheres Regulations 2002) and has technology that can measure 400 different gases.

Assentech provides the repair element of LDAR, using our state-of-the-art and award-winning Vent-Less test bench. Our trained technicians will visit your facility to test, calibrate, service and repair breather valves to issue you with an irrefutable Leak Test Certificate and API2000 Test Report to demonstrate your compliance. This certification will provide vital defence against scrutiny.

Assentech can also arrange for your leaking breather valves to be sent to Assentech for repair and returned back to your facility. The award winning Vent-Less test bench technology is revolutionising testing and identifies individual breather valve performance, functionality and leak rates enable real data for evidencing emission reduction.

OGI camera footage

Seen Through the Human Eye

EXPERT CONSULTANCY AND SPECIALIST SERVICES TO KEEP YOU SAFE, COMPLIANT AND PROFITABLE

BREATHER VALVE SERVICES

- Breather Valve Sizing, Suitability, and Selection

- Breather Valve Calibration, Testing and Resetting

- Individual Breather Valve Leak Testing/Quantification for Both Pressure and Vacuum Ports

- Breather Valve Inspections, Overhaul, and Service Programs – either Onsite or Offsite

- Breather Valve Pre-Commissioning: Verifies settings according to spec/set point, ensures functionality as designed, confirms compliance with API2000 Section 5.4, evidences best practice and duty of care

REGULATORY COMPLIANCE

- Regulatory and Compliance Advice

- Breather Valve API2000 / ISO28300 Test Reports

- LDAR Audits and Services- Onsite Leak Source Surveillance, Reporting, and Breather Valve Repair

- Tank Venting Risk Assessment and Corrective Measures Support

- Consultancy Support for HAZOP Reviews

- Regulation 61 emission source detection surveys with OGI technology (compliant with Method 21)

SPECIALIST MAINTENANCE

- Onsite/Offsite Technical Advice and Support of Complex and Challenging Tank Storage, Fluid Transfer or Process Safety Applications (Industry Expert)

- Technical Support and Evaluation Specialists

- Internal Floating Roof (IFR) Supply, Supervisor Support, and Installation Packages (Factory Authorized)

- Loading Arm Supply and Maintenance

- Epsilon Coupler Supply, Leak Testing, and Certification (Factory Authorized)

- Site Asset Registering with Tank Venting Tables

TRAINING COURSES

- Learn how to operate and understand the functionality, features, and measurement controls of the OPGAL OGI Camera, compliant with Method 21. (Industry Expert)

- Learn from Industry Leaders: Hands-On Training in Breather Valve Servicing and Testing in accordance with API2000 Section 5.4 / ISO28300 Section 6.4 to reduce emissions, improve safety and evidence compliance. (Industry Expert)

How Can Assentech Assist You?

- Advanced OGI Surveillance:

- State-of-the-art Optical Gas Imaging (OGI) surveillance.

- Highly experienced and specialized team.

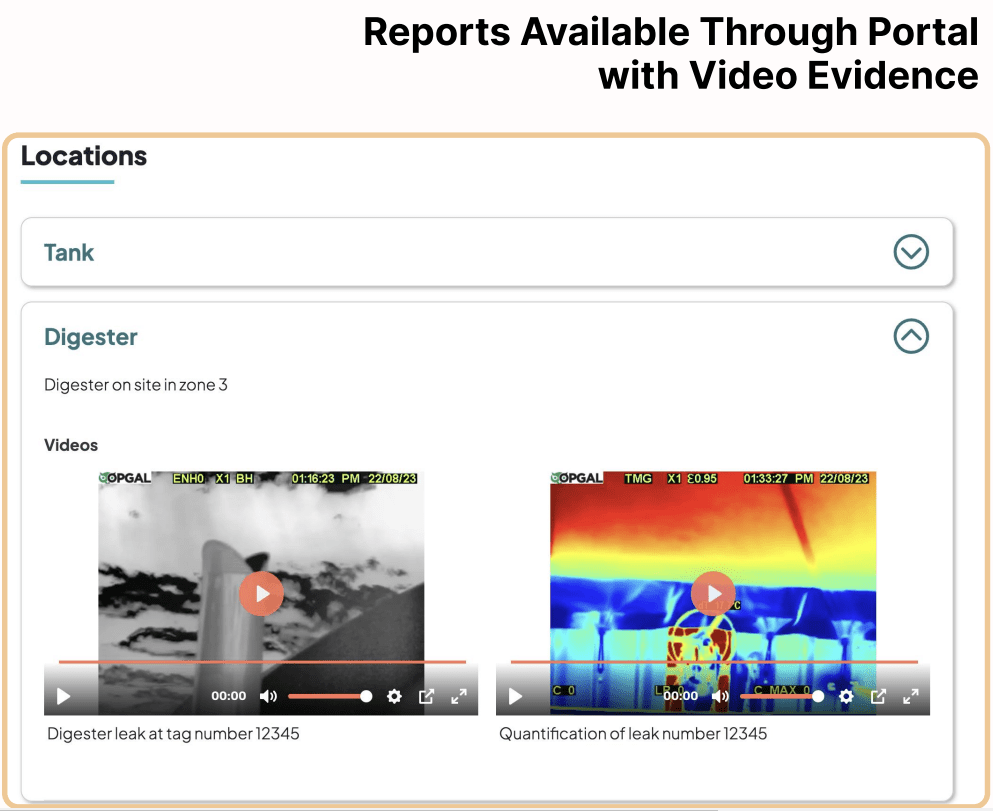

- Access to Portal for custom reports and video evidence.

- The surveillance will be conducted by a highly skilled operator who is thoroughly familiar with the technology and the specific requirements of LDAR surveys. This ensures that every aspect of the survey, including strict data reporting, is managed with the utmost expertise and precision.

- Breather Valve Leak Rate Reports:

- Crucial for environmental reporting and emission reduction, empowers operators with accurate data, enabling informed decision-making.

- Rarely provided by manufacturers from new due to lack of proper test equipment.

- Leak rate tests available at various stages:

- From New

- Pre-Commissioning (Before Install)

- During Routine Maintenance (Aging Plant Management)

- As Needed for Environmental Surveillance and Accountability

- API2000 Test Reports:

- Available for vacuum and pressure ports.

- Identifies risks in valve functionality.

- Ensures valve meets datasheet specifications and intended purpose.

- Facilitates risk mitigation.

- Assentech On-site:

- Available servicing at Assentech’s premises.

- Includes pre-test, routine maintenance, new soft goods kits, and post-test.

- Generates individual API2000 Test Report with leak rate data.

- Vent-Less test certificate included.

- Supply of Vent-Less Test Bench:

- Three models are available for facilities, regulators, service companies, and laboratories.

- Follows API2000/ISO28300 test protocol.

- Provides rapid, accurate, traceable, and irrefutable test certification within minutes.

- Fully automatic with repeatable accuracy.

Beyond LDAR Compliance: Key Benefits

- Protects Workforce, Environment, and Facility: Safeguards against harmful emissions.

- Supports Hazardous Area Zone Allocation: Assists in proper zoning and safety measures.

- Reduces Costs: Minimises media loss, prevents fines, and improves operational efficiency.

- Extends Equipment Longevity: Increases the lifespan of tanks and peripheral equipment.

- Enhances Stakeholder Confidence: Builds trust among stakeholders.

- Demonstrates Duty of Care and Best Practices: Showcases commitment to safety and excellence.

- Provides Robust Legal Defense: Irrefutable API 2000/ISO 28300 test reports strengthen legal positioning.

- Boosts Insurance Underwriter Confidence: Increases assurance for insurance providers.

- Ultimate Risk Mitigation: Offers unparalleled protection—how else can you safeguard your interests?