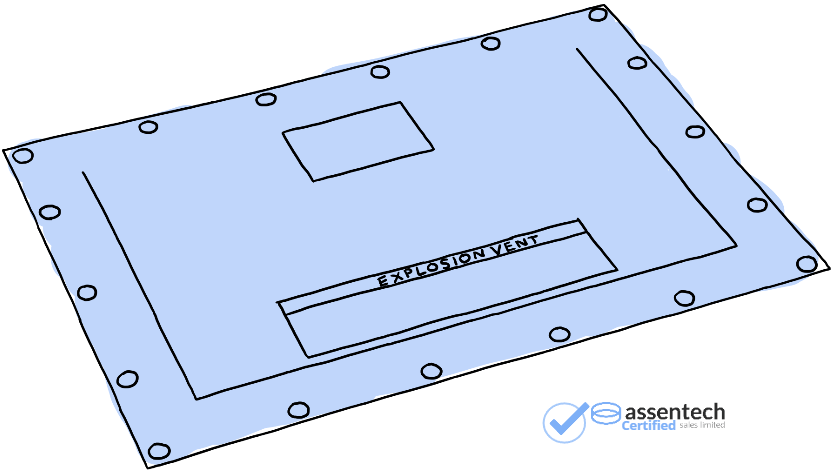

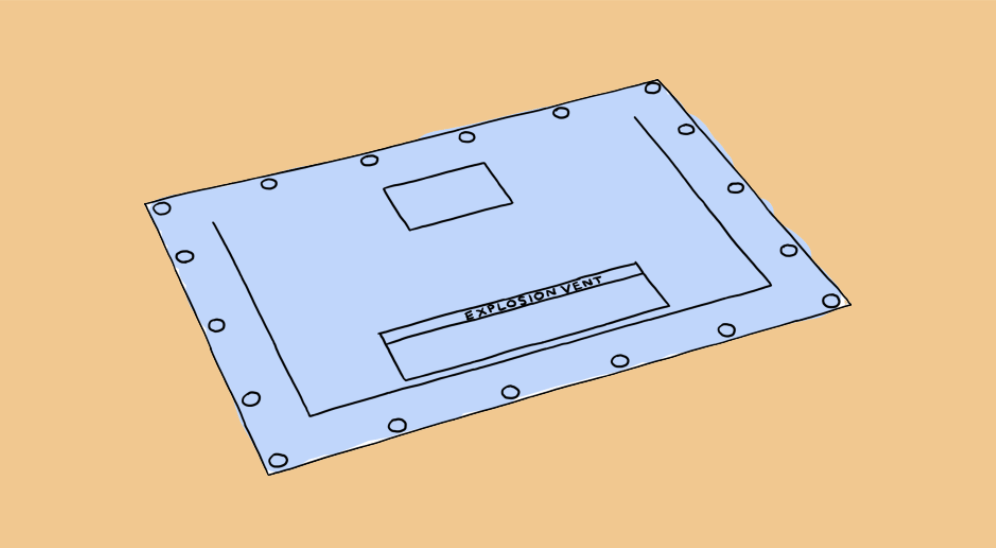

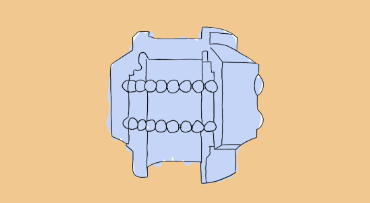

Burst Panels are essential safety devices specially crafted for the control of combustible dust explosions. These ATEX-certified explosion venting panels are high-performance vents meticulously designed to provide a rapid and non-fragmenting opening in industrial process equipment during a dust or gas explosion. By doing so, they not only allow for the release of expanding flames and pressure through a planned pathway, ensuring unmatched safety, but also ensure that excess overpressure is vented. Consequently, the internal explosion pressure is reduced to a level that the process equipment can comfortably withstand.

Lightweight, vacuum resistant, and non-fragmenting, our Burst Panels exhibit superior performance features. They can be customised further with optional accessories such as weather covers and burst indicators. With a diverse range of panels tailored for an array of applications, Assentech stands out by offering unrivalled technical and after-sales support. Trust Assentech for your explosion venting needs and experience the industry-leading safety delivered by our Burst Panels.

Compliance with International Standards

Our Burst Panels meet and exceed global standards, ensuring the utmost reliability and performance. For different product ranges, we abide by varying international standards, in addition to our steadfast commitment to ISO9001.

Our Burst Panels are in strict compliance with EN14797 (pertaining to Equipment/Device), EN14491 (specific to Dust explosions), EN14994 (associated with Gas explosions), and EN16009 (for Flameless Venting Devices). Further emphasising our dedication to excellence, our panels also meet the NFPA 68, EAC, and are proud recipients of the FM 7730 Approval.

Ensuring consistent safety and exceptional functionality, our Burst Panels stand as an embodiment of quality and dependability across diverse industry applications.

Get in Touch

We invite you to book a complimentary 1-hour online session with our experts. This online consultation will provide you and your team an opportunity to delve into critical areas such as Tank Venting, Valve Testing, and an in-depth understanding of API 2000 and ISO 28300 standards. Our specialists are ready to introduce you to the most advanced techniques and best practices available in the industry. Please don’t hesitate to reach out to us, contact us today to schedule your session.

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

Documentation List

Individual documentation can be requested from the following list as applicable

- Certificate of Conformity

- Certified capacity flow curves

- ATEX Certification

- Material test Certificate

- Manufacturing Record Book

- Certificate of Origin

- Positive Material Procedures and Test Reports

- GA Drawings

- Hydrostatic and Pneumatic Test

- Pressure Test Reports and Certification

- Surface Preparation and Coating Reports

- Installation, Operation and Maintenance Manual

- Shipping and Maintenance, Preservation Procedures

- Inspection and Test Plan

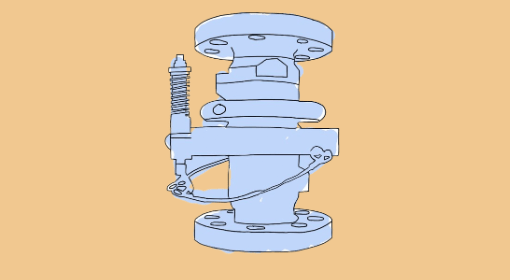

Certification and Compliance

Assentech provides comprehensive certification and compliance documents for all our products. These include:

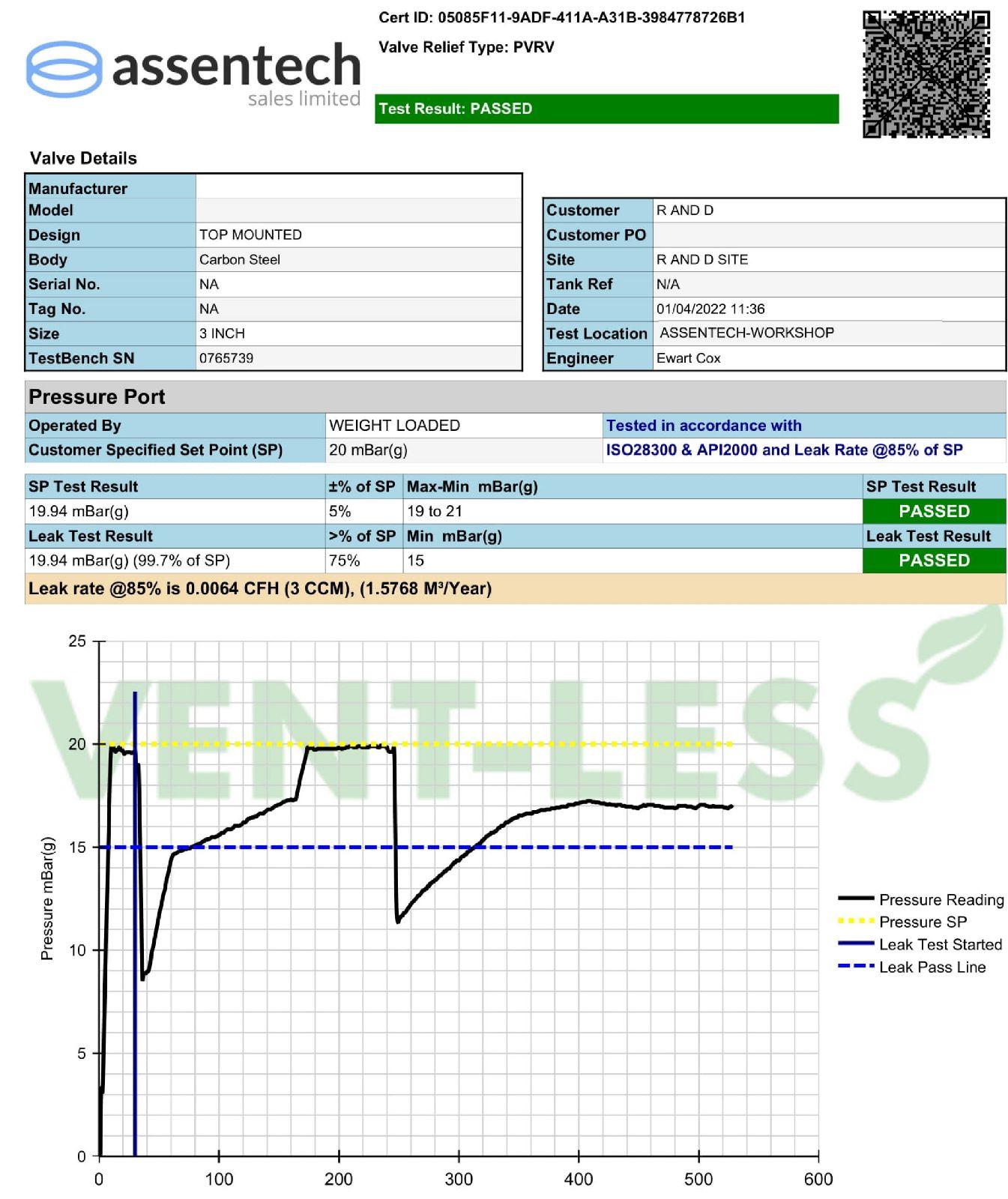

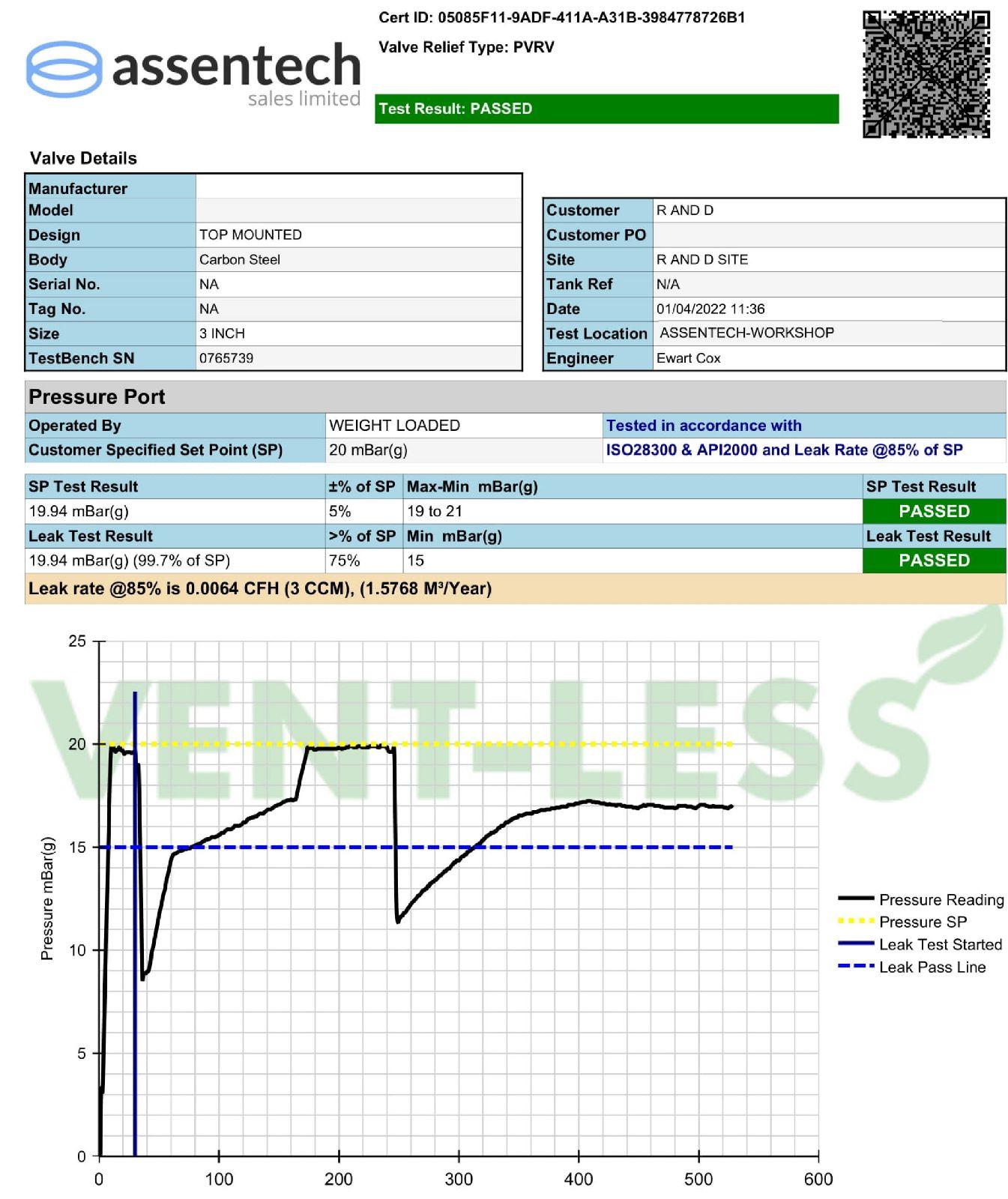

- Valve Calibration / SetPoint Certification

- Individual Vent Leakage Certificates in accordance with ISO28300 or API2000 on both vacuum and pressure ports.

This rigorous certification ensures maximum sealing and no emission loss, leading to increased confidence from regulators, the public, and environmental bodies.

Evidence Duty of Care

Assentech is dedicated to providing high-quality after-sales support to our customers. We stand out as the only authorised repair and service centre equipped with the necessary technology, certification, and knowledge to detect leakage, test performance, and maintain your Breather Valves to keep you safe and compliant. With full access to factory spares, all our processes are fully traceable, guaranteeing the best in customer care.

Responsible Procurement

Assentech believes in being fully transparent and accountable in our procurement processes. We provide a full and comprehensive range of industry-specific compliance sheets, certificates, and reports available upon request. This ensures our customers in the tank storage industry and beyond have full insight into the documentation that supports their choice of products and services.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation's needs.

Process Safety Equipment Product Range

Bursting Discs

Burst Panels

Swivels

Break-Away Couplers

Rack monitors

Assentech Academy - Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact

Assentech Academy

Educating Industry on Best Practice

- Valve Specification

- Procurement

- Installation and Commissioning

- Servicing

- End of Life Recycling

- Environmental Impact