Tank Truck- OPW Bottom Loading Advantages

We all want the best in terms of loading systems. We want the fastest loading and unloading operations.

Commercial value is really important both in terms of capital investment and with regard to on-going operational costs, – so products that are both easy to use and maintain are key. Safety is critical and spill prevention, operator safety, fire prevention and efficient vapour recovery must be high on everyone’s agenda.

With all this in mind; OPW loading systems can support you to achieve all of the above; giving you peace of mind, quality, decades of experience and value for money long-term.

Bottom loading is a method of filling tank trucks by pumping Chemical, Petrochemical or Petroleum products into cargo tanks through a system of valves and fittings mounted under a truck. While the traditional method of loading (Top Loading) is through the open manhole covers on the top of the tank truck.

Tank Trucks Bottom Loading Key Advantages:

- Fire prevention: The process of top loading involves the splashing of fluids during loading. This causes a significant build-up of electrical charges within the compartment itself. Electrical discharges can occur for many reasons. The opportunities for generating a spark are increased by the presence of moving men and equipment on the top of the truck. Eliminating this reduces the risk. Grounding systems associated with the overfill prevention system reduce the opportunity for sparks even further.

- Spill prevention: Every petrochemical product spill is potentially serious from the aspects of fire safety, pollution control and loss of valuable product. The dry disconnect features associated with the API bottom loading standards reduce or eliminate the potential for product spills at both loading terminal and the service station. Also the overfill protection system as specified by the API prevents the possibility of serious product spill at the terminal.

- Operator safety: Loading a tank truck from the top requires that a person work on a narrow walkway on the top of the truck high above the pavement. The operator has to handle awkward equipment and takes different positions to perform his task. At the same time, the operator may be outside in poor weather conditions and he may well be breathing high levels of chemical/petrochemical/petroleum vapors, which may affect his performance. The same operator is responsible to react quickly in case of an emergency. Loading a tank truck from the bottom, the operator is standing safely on the ground throughout the loading process. During the actual loading, the operator is normally standing at the control ready to react quickly in case if an incident.

- Vapour recovery: The transfer and transportation of petrochemical/chemical products contribute significantly to the levels of pollution in an area. The practice of bottom loading makes the efficient recovery of petroleum /petrochemical /chemical vapours easy compared to top loading installations. A recovery of 95% of the vapours can be eliminated in a safe manner.

- Avoidance of product contamination: During top loading, the manholes on the top of the tank truck are open, and easily contamination can take place (rain, snow, dust, loose items). In bottom loading there is no open manhole, but a closed system during loading.

- Faster truck loading: Several factors combine to make bottom loading a much faster method of filling a truck than top loading. First, the operator does not have to go the top of the tank truck to open the man hole and put the loading arm in its loading position. Manoeuvring bottom loading arms towards the tank truck adaptors is easier. Also more compartments can safely be filled at the same time, foreseen that the required equipment is installed. Loading rates are often much higher than in top loading as well. Top loading rates are in the range of 1100-1500 lpm, were for bottom loading rates are in the range of 2100-2800 lpm.

- Less expensive loading islands: Bottom loading islands are significantly less expensive to build and maintain than top loading islands. The walkway and overhead loading structure associated with top loading are eliminated. The savings can be quite substantial when the time comes to replace loading islands.

We supply a broad range of loading equipment and complete loading platforms, gantries and racks.

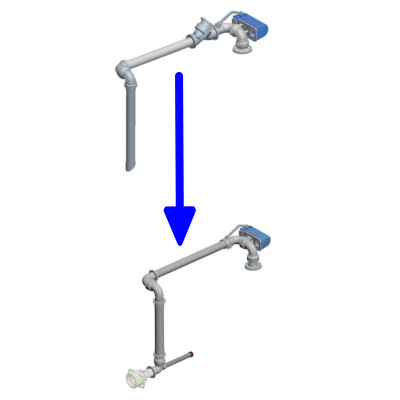

Vapour Recovery Arms

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.