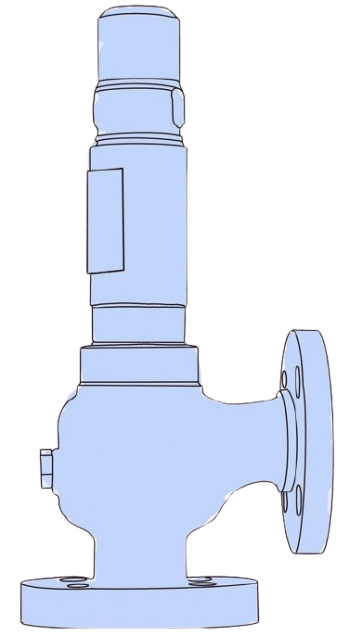

We’re excited to announce the addition of Safety Relief Valves to our 2025 product supply portfolio! These high-quality, fully compliant safety devices are designed to provide reliable performance and come complete with robust documentation and certification to withstand scrutiny. Built to last, our safety relief valves offer exceptional durability and peace of mind for your critical safety needs.

Assentech offers a comprehensive range of safety relief valves designed to meet the most demanding industry requirements. Built to the highest quality standards, our valves ensure reliable protection against overpressure situations, safeguarding equipment, personnel, and the environment. Safety relief valves are critical safety devices that automatically release excess pressure to protect systems, prevent equipment failure, and maintain operational safety. They are essential in industries such as oil and gas, chemical, pharmaceutical, food production, and cryogenics.

Valve Design and Materials

Our safety relief valves are available in semi-nozzle and full-nozzle designs, ranging from ½” to 12”, and are constructed from a variety of high-performance materials:

- Carbon Steel and Stainless Steel: Ideal for general industrial applications.

- Exotic Materials: Including Inconel, duplex, super duplex, and Monel, designed for severe service environments and extreme conditions.

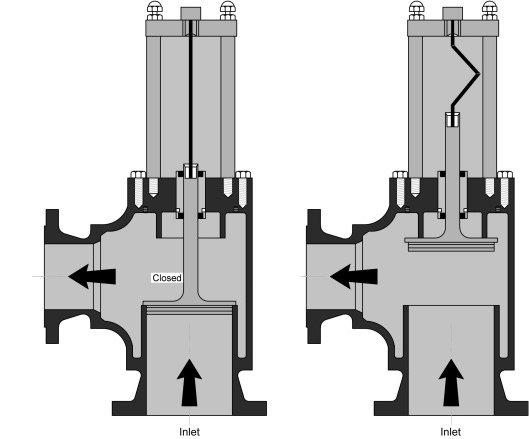

Welding-Free Design

Our pressure industrial safety relief valves are designed without requiring welding, eliminating the need for non-destructive testing (NDT). This design innovation ensures reliable, cost-effective performance and simplifies compliance.

Types of Safety Relief Valves we supply:

Industrial Safety Valves: Designed for heavy-duty processes

Hydrogen Safety Valves: Safe handling of hydrogen under demanding conditions

Hygienic Safety Valves: Meeting the highest hygiene standards for food and pharmaceutical industries

Cryogenic Safety Relief Valves: Engineered for extremely low-temperature applications

Hydraulic Safety Valves: Protecting hydraulic systems from overpressure

Pressure Safety Valves: General-purpose valves for various applications

Thermal Safety Valves: Specifically designed to relieve pressure caused by thermal expansion

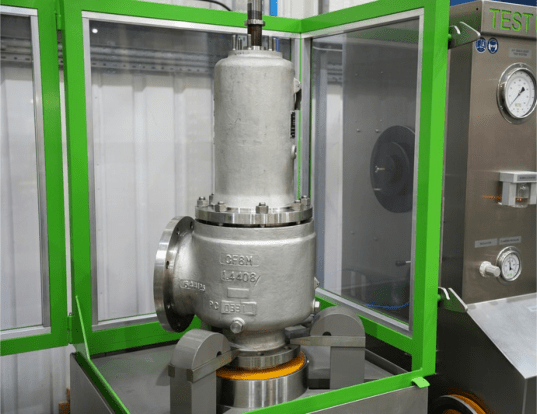

Compliance and Certification

All valves are manufactured and supplied in accordance with leading international standards to ensure safety, reliability, and performance, including:

API 520: Sizing, selection, and installation of pressure-relieving devices.

ISO 4126-1: Safety devices for protection against excessive pressure.

ASME Section VIII: Pressure vessel design code for pressure-relief devices.

AD2000 Merkblatt: Standards for pressure equipment in Europe.

API 527: Certification for set pressure and tightness performance.

In addition, we provide:

3.1 Material Certification: Covering the body, bonnet, nozzle (where applicable), and disc.

Data sheets and Sizing Calculations: Detailed and compliant with the relevant standards.

Customised Document Packs: Tailored to suit specific project requirements, with full

traceability available upon request.

Our in-house painting facility also allows us to meet customer-specific paint systems for

any operational or environmental requirements.

How Can an Overpressure Situation Occur?

All valves are manufactured and supplied in accordance with leading international standards to ensure safety, reliability, and performance, including:

Overpressure situations can arise from:

- Thermal Expansion: Increased temperature in a confined system

- Equipment Failure: Malfunctions such as pump or valve failures

- Process Upsets: Sudden operational changes or blocked discharge lines

Valve Sizing and Maintenance

Correct sizing is critical to ensuring safety relief valves function as intended. Assentech offers expert

consultancy to specify, size, and recommend the right valve for your application, ensuring compliance

with API 520, ISO 4126-1, and ASME Section VIII.

Regular inspection and maintenance are also vital to extending valve lifespan and ensuring optimal

performance, demonstrating compliance and best practice.

Contact Assentech today to discuss your safety relief valve requirements. Our team of experts can assist with specifying, sizing,

troubleshooting, and providing technical consultancy to ensure you have the right solution for your application. With our extensive

range and commitment to quality, we deliver the performance and reliability you can trust.

Visit our Maintenance & Inspection page below to explore our innovative solutions for your equipment. Or get in Contact with the team to discuss your organisation's needs.