Internal Floating Roof Inspection, Maintenance and Repair in accordance with EEMUA 159 and API 653

We work with customers across a number of sectors and have installed Internal Floating Roofs in tanks across a broad range of sizes and applications.

We collaborate with our customers from specification of the design of their roofs to meet their application requirements through to full installation; ensuring full accordance with API 650 is achieved.

Assentech Rapid Response and Service Ltd additionally offers Internal Floating Roof inspections, with maintenance and any repairs carried out in accordance with the published Engineering Equipment and Materials Users Association (EEMUA) – Publication 159 and API Standard 653. This service covers not only Assentech installed roofs but all third-party Internal Floating Roofs. Full documentation is supplied to ensure Tank Farm Operators have clear evidence of effective and compliant maintenance routines.

Why Choose Assentech?

We understand storage tanks and we understand the process industry. We take a consultative approach to customer’s requirements and are happy to talk through your tank drawings with you. We deal directly with manufacturers who are confident in our ability to accurately capture your requirements and who offer us the full support we demand. Buying an IFR is only part of the story; it also has to be installed. It is a well-known fact that the teams who perform the installation will significantly impact the effectiveness and lifespan of the IFR. It is therefore vital to obtain references. Please click here for some of our customer testimonials.

✓ Internal Floating Roofs Inspection / Conditions Report

As an approved supplier and installer, we carry out inspections and repairs of IFR’s with respect to their condition and effective function. It is important to note that we provide this service for all makes of equipment, not just Matrix Applied Technologies IFRs. We pride ourselves on offering a quality service through our detailed knowledge of legislation, using documented standard operating procedures in accordance with EEMUA Publication 159 and API 653 and developing written schemes of examination.

Our work includes:

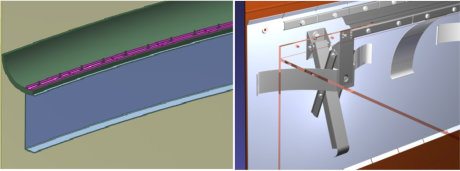

- Deck Structural Inspection and Repair (Deck Sheeting, Rims, dip funnels and manways, etc).

- Floating Roof Seal System inspection/repair/replacement: Low-cost wiper seals can wear quickly with a service life of three to five years before gapping occurs. Stainless steel shoe seals give the best long-term wear resistance over time but should still be inspected regularly.

✓ Technical Seminars

If you or your team want to know more about any aspects of Tank Safety equipment; including items such as Geodesic Domes, Internal Floating Roofs, Venting, Fire Relief etc. we will be happy to run a technical seminar or lunch and learn session for you. We make no charge for the sessions to end-users for groups of 5 or more people. Please use the following form to register your interest for an event:

Related…

Contact us

If you would like to place an order or find out more, please email info@assentech.co.uk, call on +44 1726 844 707, or fill in a contact form here.