Need advice on the right dry break coupler?

Our technical expertise extends to determining functional suitability and media compatibility. We have access to factory-specific specialist knowledge, providing you with a comprehensive support package. We champion a thorough and systematic approach to maintenance, as detailed in our written scheme of examination for all activities.

End Users are responsible for maintaining comprehensive records on all site assets, which must include historical information on purchase, inspection and maintenance for each asset as part of a site central database. Having this complete history at your fingertips can aid in regular reviews and continuous improvement of your fluid transfer activities.

Additionally, the Assentech high integrity safety range of products includes break-away coupling that protects your facility from the consequences of a drive-off while still connected to the loading hose. Break-away couplers can operate automatically using break pins or actuated manually by the operator. Break-pins need regular inspection in order to avoid unplanned activation. With our expertise, innovative technology, and dedicated support, we set the industry standard for tank venting advice, product supply, and inventive solutions. Choose Assentech for a partnership that keeps you safe, compliant, and profitable.

Discover the vital role of regular upkeep for your OPW Kamvalok, Epsilon, and Drylok products below

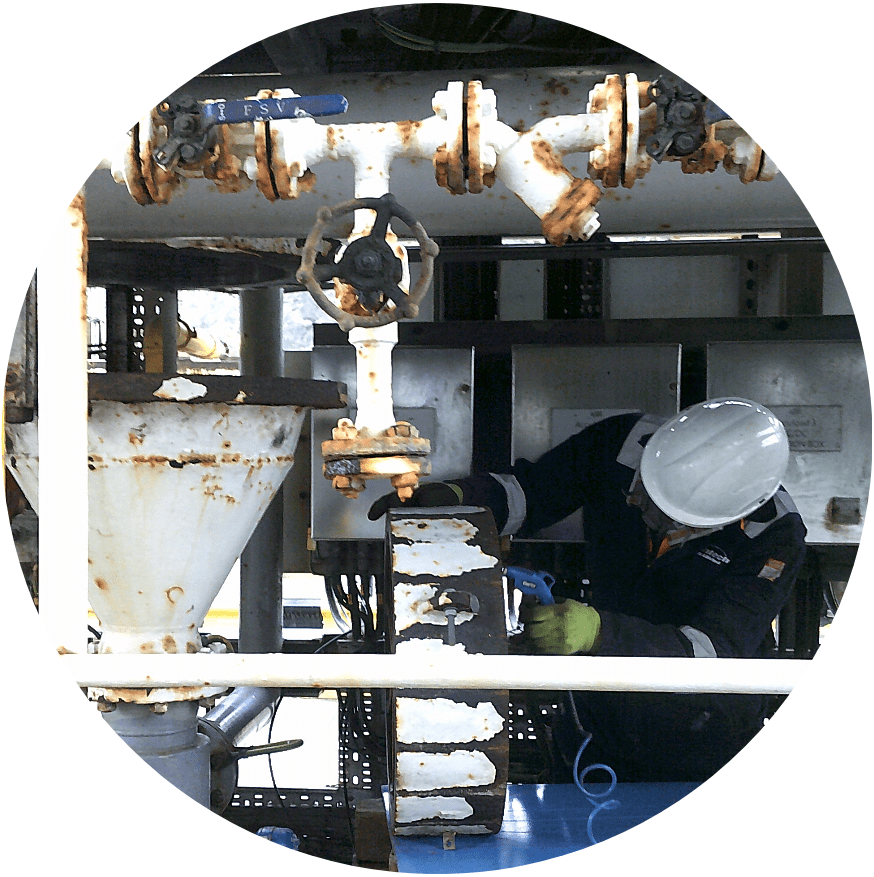

The primary safety attribute of a dry disconnect coupler is its ability to operate with minimal fluid loss upon separation. Conventionally, fluid transfers from the coupler to the adaptor. Given that both halves might be pressurised when separated, it’s crucial for them to seal effectively without dripping. In high-traffic areas, couplers might be operated every 20 minutes, 24/7. Their functionality depends on the flexibility of the seal and smooth, uniform mating surfaces. It is essential that all materials in the seal are compatible with the process to ensure safe operation and long service life. The consequences of a coupler or adaptor failure could range from losing a day’s production to fatalities, making a preventative maintenance programme crucial.

Dry disconnect couplers are ubiquitous on all COMAH sites and should be assetised so that service history records can accumulate over time. A written scheme of examination ensures these critical assets are regularly assessed for continued suitability in their intended service. As processes evolve, it’s vital that all process equipment remains functional and reliable. Without routine maintenance and inspection, an operator won’t be able to monitor the condition of these critical safety devices. Regrettably, many couplers and adaptors are only repaired when they break or begin to leak, putting the business, employees, and environment at risk. Due to the exotic nature of many seal materials, spares often have a 6-8 week lead time. Assentech aims to maintain stock or spare parts kits for urgent repairs.

Why Assentech?

| Factory technical support to ensure application suitability | Innovator of Vent-Less Technology, revolutionising tank breather vent testing to measure, monitor and reduce fugitive emissions | ||

| Accredited to ISO 9001, ISO 14001 and ISO 45001 by a UKAS certified body | Innovative solutions ranging from software to mechanical design | ||

| Fully traceable factory testing and calibration equipment | Manufacturers’ authorised service centre with access to factory technical support and maintenance updates. | ||

| Modular training programs establishes and tracks internal technical competence on task specific service activities | Representation on API2000 and ISO 28300 International Standards Committees | ||

| Tank storage, process safety and fluid transfer troubleshooting and maintenance support | Assentech’s comprehensive Service Reports and Test certification evidences best practice, compliance and duty of care | ||

| Experienced with COMAH sites, handling hazardous substances, RAMS generation and risk mitigation | Over 20 years of engineering expertise in the field of tank venting | ||

| Calibrated testing instrumentation is traceable to national standards | Consultative approach to cater to unique client requirements | ||

| Protected through a comprehensive Professional indemnity and Public Liability Insurance package | Assurance of customised, best-suited equipment for specific needs | ||

| Close collaboration with manufacturers to ensure optimal equipment selection | Capability to provide solutions in a variety of materials, including exotic and fibre reinforced plastics |

Why Assentech?

Advisor to the Environment Agency providing support and maintenance advice on best practice on tank storage applications

Innovator of Vent-Less Technology, revolutionising tank breather vent testing to measure, monitor and reduce fugitive emissions

Accredited to ISO 9001, ISO 14001 and ISO 45001 by a UKAS certified body

Innovative solutions ranging from software to mechanical design

Fully traceable factory testing and calibration equipment

Manufacturers’ authorised service centre with access to factory technical support and maintenance updates.

Modular training programs establishes and tracks internal technical competence on task specific service activities

Representation on API2000 and ISO 28300 International Standards Committees

Tank storage, process safety and fluid transfer troubleshooting and maintenance support

Assentech’s comprehensive Service Reports and Test certification evidences best practice, compliance and duty of care

Experienced with COMAH sites, handling hazardous substances, RAMS generation and risk mitigation

Over 20 years of engineering expertise in the field of tank venting

Calibrated testing instrumentation is traceable to national standards

Consultative approach to cater to unique client requirements

Protected through a comprehensive Professional indemnity and Public Liability Insurance package

Assurance of customised, best-suited equipment for specific needs

Close collaboration with manufacturers to ensure optimal equipment selection

Capability to provide solutions in a variety of materials, including exotic and fibre-reinforced plastics

Urgent Facility Downtime?

Assentech can request expedited spares and replacement units as well as supplying experienced technicians to attend your facility and provide comprehensive and bespoke support in normal working hours but also on request, we do offer engineering support outside of normal operating hours

Our Technical Advice

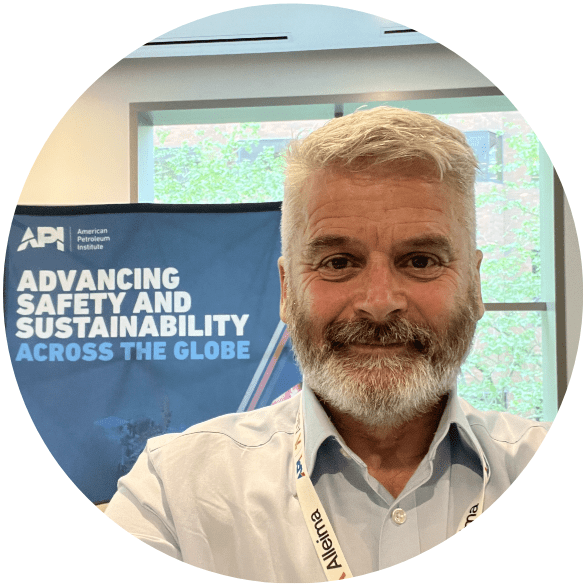

Assentech has an enviable reputation with 25 years of tank venting experience, technical support, challenging tank venting applications, legislative compliance and maintenance practices to keep your facility safe, compliant and profitable. Our Managing Director sits on two international standards committees, is currently writing an environmental annex for API2000 and supports the Regulators on best practice. With prior arrangement, Assentech can be available for On-Site Consultancy (Site Visits and Technical Expertise).

Get in Contact with the team to discuss your organisation’s needs